Henson Technical Data and Specs

The info on this page is a copy from Henson Shaving. Comments or questions regarding the information found on this page should be directed by email to support@hensonshaving.com.

General Specs

Safety and shaving performance

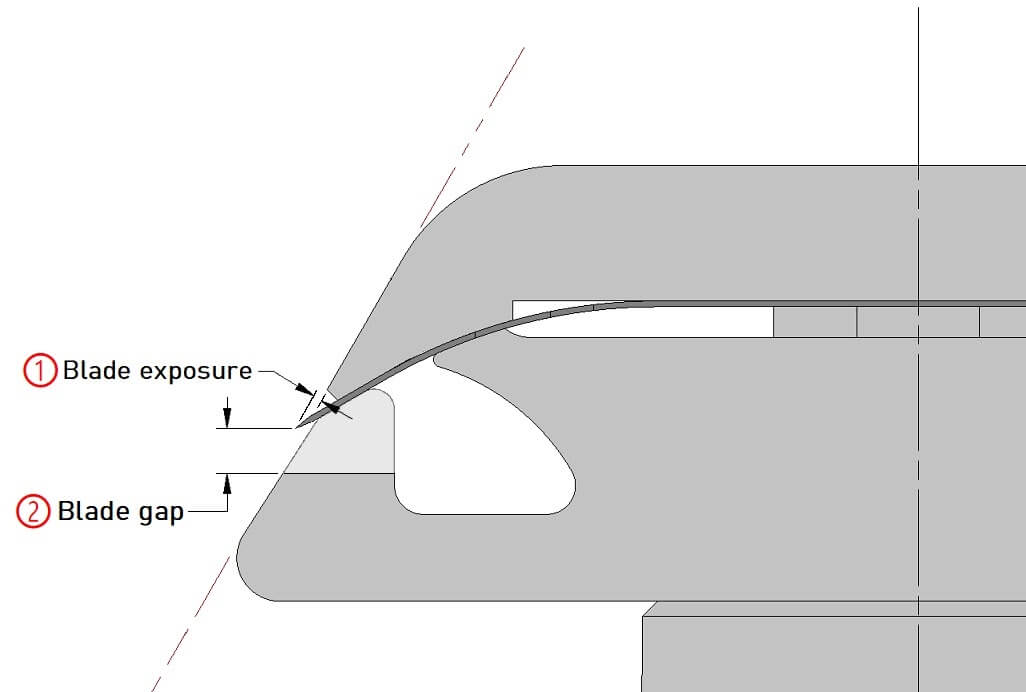

The exposure and the blade gap (① and ② in Figure 1) are two key features that determine the safety and cutting effectiveness of the razor, often described by the word aggressiveness. Typically, there's a predictable relationship between the performance of razor with a given level of aggression and its safety, meaning the likelihood of nicks, razor burn or general irritation while shaving effectively and properly. The Henson Razor’s design incorporates safer, flattened shave plane surfaces in conjunction with slightly increased exposure and blade gap, combining to offer a strong balance of shaving effectiveness and shaving safety.

Figure 1: Blade gap and exposure

Figure 1: Blade gap and exposureSafe shave plane

The mostly flat faces that form the shave plane create reliable and secure contact from the razor to your face, minimizing the chance of unwanted skin contact with the blade. This attribute means that our blade gap and exposure can afford to be slightly higher, while still being considered a mild-medium aggression level. The result is increased shaving performance without compromising the level of safety.

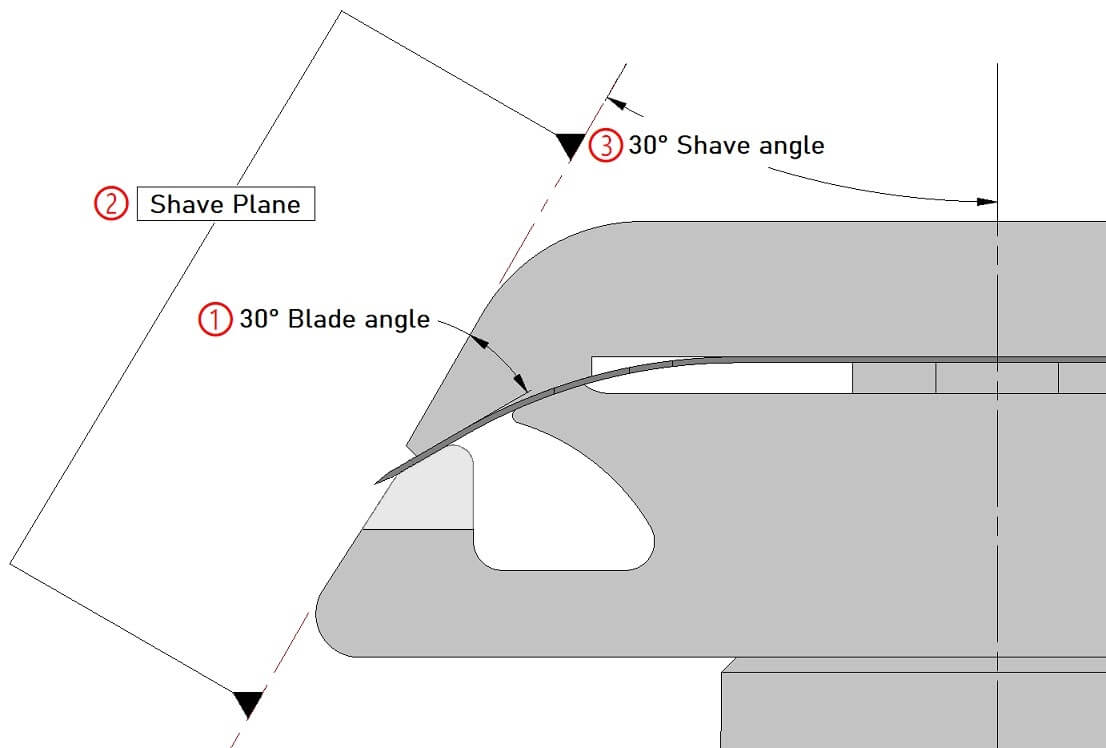

Ergonomics of the angles

The blade angle (① in Figure 2) is the effective angle of the blade as it makes contact with the skin, measured from the shave plane (② in Figure 2). It is said that the ideal blade angle is 30°. We have achieved that angle, as many razors do. What we have also managed to do is keep our shave angle (③ in Figure 2), or handle angle, at 30° as well. This is less common among razors. We do this by pressing the blade into a radius that bends the edges of the blade a full 30°. The handle angle being 30° allows your hand and strokes to be performed in a more comfortable and controllable position. As an analogy, when raking leaves we pull the rake at nearly 30° to the ground. The higher the angle gets, closer to 90°, the more unstable and uncontrollable the action is. Using our razor allows a more controlled stroke since it is at 30° (compared to 45° or more for most razors). If you are accustomed to shaving with a disposable type razor, the transition to a safety razor will be a lot easier due to this feature.

Figure 2: Razor angles

Figure 2: Razor anglesRigidity of the blade

The design of the Henson Razor involves pressing the blade into a radius, bending the edges to achieve the 30° blade and shave angles, and introducing tension on the blade. In conjunction with short free-end and clamp distances, the result is an extraordinarily rigid blade edge. The free-end distance (① in Figure 3) is the distance from the tip of the blade to the first point of contact on the cap. The clamp distance (② in Figure 3) is the distance from the tip of the blade to where the top cap and base plate clamp the blade. As you can imagine, the longer either of these distances is the more flimsy and prone to chatter the blade is. Because of the Henson Razor’s rigid design, blade chatter and deflection are minimized when shaving, producing a more consistent and predictable shave that doesn't miss as many hairs. Additionally, the life of the blade may be higher.

Figure 3: Factors affecting blade rigidity

Figure 3: Factors affecting blade rigiditySmooth hair evacuation

Smooth hair evacuation makes for a quicker and safer shave. Razor clogging due to poor evacuation of hair causes not only the need for more rinsing and more strokes, but also a higher likelihood of irritated skin and nicks. Irritated skin can occur because clogged hairs block new incoming hair from effectively being cut. Similar to raking leaves, the raking or cutting area becomes saturated and no longer functions correctly. At this point, the razor is being moved across your skin without effective cutting, leading to razor burn. Additionally, the shaving effectiveness becomes sporadic and unpredictable, leading to a "start-stop" shaving action where a portion of the blade will alternate between effective and non-effective. This unpredictable shaving action can result in unexpected changes in cutting performance which can increase the chance of nicks. We designed large and ergonomically shaped channels, allowing the movement of cut hairs to be as free flowing as possible from the blade tip to where it exits the base. This allows for a larger window of safe and effective shaving, with a more gradual and predictable reminder of when rinsing is needed. In fact, our razor is so effective in allowing free flowing cut hairs, that you could go through a whole shave without rinsing once!

Figure 4: Large and free flowing channels

Figure 4: Large and free flowing channelsProper care and maintenance

The need for thorough cleaning of your razor will depend on how frequently you use it, how you clean it after each use, and how often you take the head apart. You should at least thoroughly clean the razor about every month. The thread is the only part of the razor that may benefit from some maintenance. The threads should be kept clean and free from debris, as this is important for proper function. You could also gain some benefit towards longevity by adding some oil, grease, or even petroleum jelly, to the thread on occasion. The anodized finish is not prone to corrode and should not stain. However, acidic chemicals (e.g. bleach, hydrogen peroxide) will impact the anodize and must not be used for cleaning. To achieve the greatest accuracy, performance, and life from your razor, it is also advised that when installing a blade and assembling the razor, you should ensure that there is no debris on the inner surfaces that clamp the blade in place (on both the top cap and baseplate), as well as on the face of the bushing and end of the handle.

Weight

There is no question that this razor is a lightweight. Many resources on shaving with a safety razor suggest that weight is essential and to “let the weight of the razor do the work”, but we have not found this to be quite as influential as its popularity suggests. Admittedly, many users simply prefer a heavier razor. However, we have found that shaving with a lightweight razor is completely effective and can be quite a refreshing experience. It is incredibly easy to hold a light razor both delicately and decisively at various angles and with various handholds. There is no need to tighten your grip just to overcome the weight of the razor itself. After shaving with a heavier razor, for some it is actually noticeable that shaving with a light razor is less fatiguing. Having a light razor to maneuver feels very nimble, quick, and dexterous as you navigate your face or body while shaving. If you are accustomed to using a heavy razor, you might need some time to adjust and learn the new feel for holding and moving our light razor decisively but without putting added pressure against your skin as you shave.

Materials

Aluminum

At 1.3 oz., this razor is ultra-lightweight and extremely agile, yet completely proficient, and is a joy to use. It is economically machined and coated with Type II anodize, which gives this razor the looks you want with the protection you need. One word to describe the shaving experience is precise. We have had great feedback from new and experienced wet shavers. The razor may have extra appeal for the ladies, or anyone who will use it on other body parts, due to its ease of maneuverability and amazing tactile feedback. By offering more “feel”, it is ideal for areas where you can't always see what you're doing.

Varying exposure

When designing the Henson Razor, we have found that in endeavouring to make an accurate razor, the biggest variable to manage is the consistency in blade width and other blade feature sizes. Manufacturing a blade not just accurately but consistently is a challenging task, resulting in variation in blade width. Consequently, our goal was to set the exposure and blade gap relative to the median size of the blade manufacturing results, though we still had to make our razor perform well when handling the complete range of sizes that can be produced. We have tested our razor using many blades but have found the best success when using Astra. The Astra blades measure very near that median size, have excellent rating and consistency of size, sharpness, durability, and of course come at a good price.

Given the range of blade widths that exist, it is actually more accurate to give a range of exposure that you can likely anticipate, rather than just a single exposure value.

| Exposure range | |

|---|---|

| Mild | .0007" - .0014" [.018 - .036mm] |

| Medium | .0016" - .0024" [.041 - .061mm] |

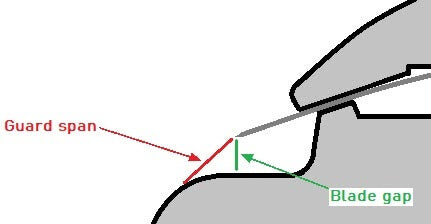

Misleading blade gap

Our blade gap may sound high and aggressive, but there is more to be understood. Many razors seem to have their blade gap specified without giving regard to the additional, more significant influence of the span between the blade edge and the safety bar (guard). While the blade gap and guard span are somewhat related, they are still independent, and the guard span is in fact far more influential on razor safety. The guard span forms the effective gap into which your skin can deform in front of (or into!) the blade. Typically, the blade gap is simply measured as the smallest distance between the blade and the baseplate near the guard, which has no direct relation to how the razor interacts with your skin. In fact, the shape and shave angle of many available razors have a guard span that can be up to two times larger than the blade gap, depending on the razor (Figure 6).

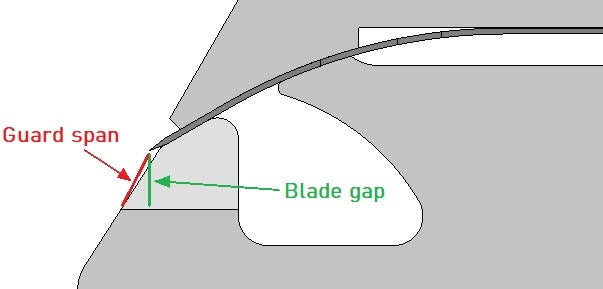

So, while we have followed the industry standard in giving our measurement the typical way, our razor design results in a guard span that is smaller than that of most razors with a comparable blade gap (Figure 7). Therefore, as mentioned, this means that while the blade gap size may sound high and aggressive, it is effectively smaller and thus actually milder than many razors with the same specified blade gap.

Figure 6: Typical Guard Span/Blade Gap relationship

Figure 6: Typical Guard Span/Blade Gap relationship Figure 7: Henson Razor Guard Span/Blade Gap relationship

Figure 7: Henson Razor Guard Span/Blade Gap relationshipAccuracy and reliability in razor performance

As mentioned above (read “Varying exposure”), the most influential attribute that affects exposure in our razor is variation in blades themselves. Initially, we thought that it was best to locate the blade width using the vee-like holes (as many razors do), but we didn’t get very far in development before we realized that this was far from correct.

There are several variances and nuances that make this choice less than ideal. First, the geometry of the contact between the “vee-like” shape and locating pins means that for every .001” of diametral clearance, the blade is able to move .0014” (see Figure 8). This is a big deal! And 40% more movement of the blade then the actual clearance? No way! The size of these “vee-like” holes ranged .003” within the measurements we had. Accounting for .0005” clearance to avoid an interference fit, this would have required us to manufacture the posts with a potential for .0035” post to “vee-hole” clearance, which considering the 40% increase would mean up to .005” blade movement. This blade movement would lead to wildly varying shave experiences due to excessive and undesirable variation in blade exposure.

In addition to this, we discovered that the distance between the “vee-holes” varies too! This added variation would require us to manufacture the posts even smaller, meaning more clearance and blade movement. These nuances speak to the complexity of achieving consistent tolerances. It is no wonder many razors have loose blades and unpredictable exposure.

Finally, when using round posts as locators and attempting to achieve a close fit, if a blade fits tightly on the posts it can become stuck as you try to remove it safely. The blade flexes, leading to binding and pinching. To overcome this either requires more force, or gripping the blade along the cutting edges, neither of which is a safe option.

For all of the reasons above, we instead chose to use the center “slot” tabs to achieve the accuracy of blade placement we were targeting. This feature is more consistently sized, does not result in a 40% increase in blade movement, does not have a varying pitch that affects location, and does not have the same tendency to bind when being removed.

Figure 8: Vee-like hole clearance problem

Figure 8: Vee-like hole clearance problemAccuracy and repeatability in machining

Accuracy and repeatability are two terms used in the machining industry, whether it be when buying a machine or measuring instrument or in setting up a machining process to run effectively. With the design of our razor, or any razor, creating an accurate product is sort of easy. You could try nine times to make an accurate razor and finally succeed, however you still need to repeat this thousands of times, which is the harder part. Achieving this requires accurate machines, precise and reliable fixtures, strong and reliable processes, rigorous and religious in-process inspection, and all of these managed by a team versed in creating and following strict procedures. For this reason, Henson has partnered with a manufacturing facility that is ISO and AS9100 certified, who understands the strong impact that process control has on repeatability.

Available Shave Angles

We have seen various comments from users or those interested in the Henson Razor, that the design and geometry of the head limits shaving to a single angle or a very limited range. In light of this feedback, we tested our razor and those of several popular competitors to understand what the available range of shaving angles was in either direction before the razor no longer cut effectively.

Here’s what we found:

| Razor | Available Angles |

Range |

|---|---|---|

| Competitor 1 | 30° - 60° | 30° |

| Competitor 2 | 35° - 70° | 35° |

| Competitor 3 | 35° - 65° | 30° |

| Competitor 4 | 35° - 70° | 35° |

| Henson Razor (Mild) | 20° - 55° | 35° |

This suggests that while the appearance of the Henson Razor suggests a narrow range of shaving angle, one can actually wander a fair bit from the ideal 30° angle during shaving and still cut effectively. In fact, it is quite comparable to other popular razors. While the eyes and brain might interpret and feel forced into the one angle based on the looks, the reality is that when shaving we learn to constantly adjust the shave angle as needed to get effective cutting based on much more than visual feedback.